What are the structural design ideas of plastic shell mold? Nowadays, with the continuous improvement of people's aesthetic concept, multi-color plastic shell mold has become a very popular plastic shell mold product. What are the processes of two-color injection molding? 1、 Process anal…… MORE

Large medical devices are relatively expensive products, and their volume is also relatively large, so it is troublesome to maintain them in case of problems. Therefore, its maintenance is very important. If there are problems, don't panic. If you can solve them, you will know how to do …… MORE

The quality of injection molding products is the premise and guarantee for the development of injection mold processing plants, so how to control the quality of injection molding products has become the primary task. What on earth should we do? 1) Do not easily determine the injection mo…… MORE

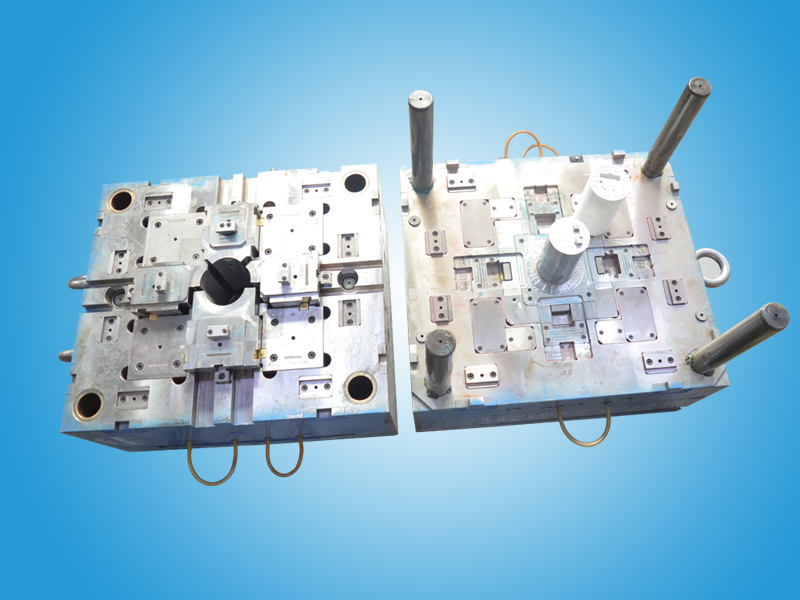

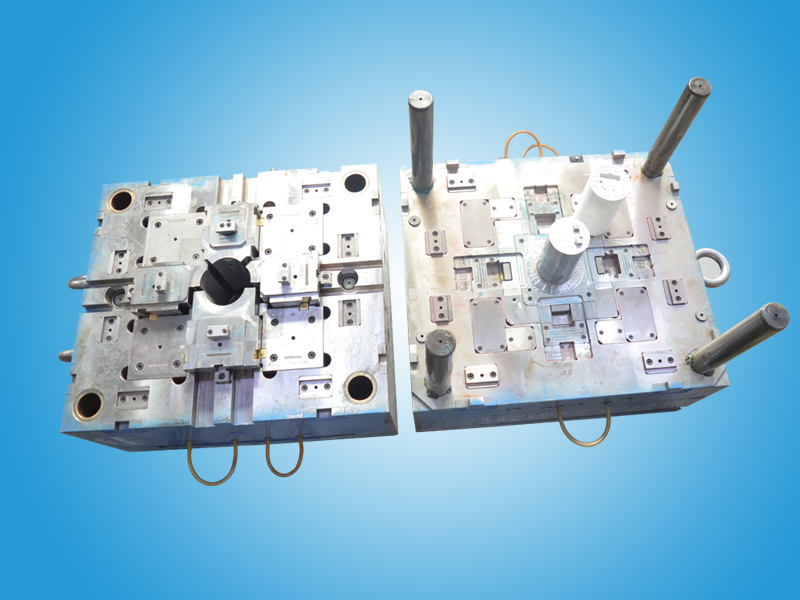

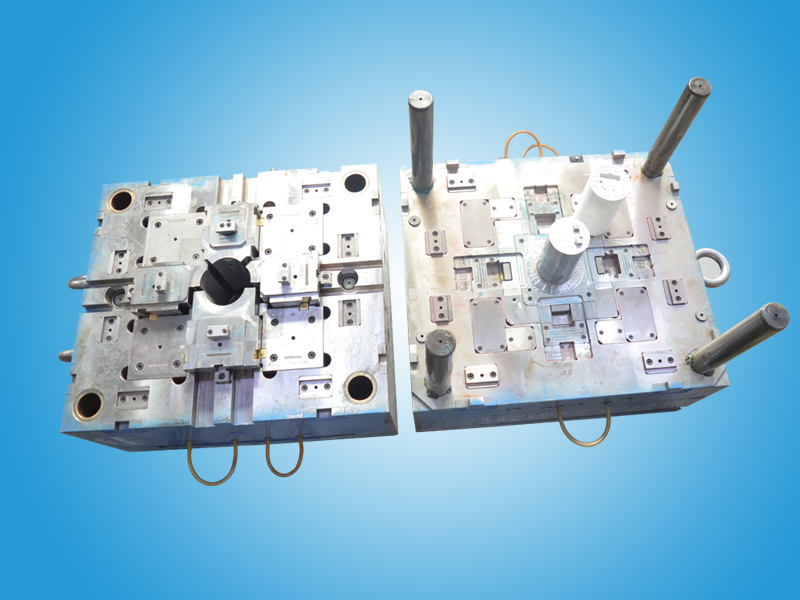

Injection molds are customized for different plastic products, but the structure of injection molds has many similarities. Therefore, in order to manufacture molds more efficiently, injection mold processing plants began to use some standard molds. In the custom mold opening, injection m…… MORE

The defect of insufficient filling during injection molding is that the mold is not full. So what is the reason for this defect, how can we find the reason for this defect, and how to solve it? 1. If we set the injection volume of the injection molding machine to the maximum during injec…… MORE

The mold processing of precision injection molded parts involves many processing procedures, and the quality of each process affects the final mold processing quality of precision injection molded parts. Therefore, we need to pay attention to all aspects in the mold processing of precisi…… MORE

In the process of injection molding, due to the uneven cooling and shrinkage of plastic in the mold cavity and the unreasonable structural design of injection molded parts, it is easy to cause various defects of products: shrinkage, weld marks, pores, deformation, galling, top injury, fl…… MORE

1. Good product structure (1) product design should try to avoid unnecessary side concave and the use of mold core pulling mechanism, so as to simplify the structure of the mold and facilitate mold processing. (2) Plastic products should have appropriate wall thickness and uniform wall t…… MORE

Plastic shell, as the name suggests, is a shell product made of plastic materials. Such products generally need injection molding. What are the key points to master in the process of injection molding? 1. Different raw materials need different temperatures during injection molding. Too h…… MORE

Injection molding production is the last step of molding injection molded parts. Before injection molding processing and production, we need to do a lot of preparatory work to ensure that injection molding processing and production are foolproof. 1、 Preparation of plastic materials 1. Co…… MORE

At present, there are six trends of modified plastics for household appliances. It mainly includes: brighter appearance color \ environmental protection, continuous improvement of safety module index, transition from automobile to household appliance lightweight, preliminary embodiment o…… MORE

1、外觀和用料 外觀和用料是一個醫療器械外殼的基本上的特點,外觀直接決定了一個外殼能不能被客戶接受的首要標準,所以現階段的外觀也逐漸偏重多樣化發展趨勢,因而在我們的測試中也占有一定的比重。用料關鍵取決于醫療器械外殼廠家選用的材料,醫療器械外殼的邊緣是否經過打卷處理,材料的好壞也會影響到防電磁輻射性能。 ……

MORE