In the processing of medical device shell, the first thing to do is to carry out blanking processing. When the good blanking is completed, the next process needs to be carried out. In this process, it needs to bend it. Bending accuracy can reflect the process accuracy of sheet metal proc…… MORE

Most of the burrs on the plastic shell of the power supply occur on the parting surface, that is, where the molten material flows into the place between the moving mold and the static mold, the sliding part of the slider, the gap of the insert, the hole of the ejector rod, etc., and redu…… MORE

The cracking of plastic injection products includes filiform cracks, microcracks, white tops and cracks on the surface of plastic shell, as well as the trauma crisis caused by part sticking and runner sticking. According to the cracking time, it can be divided into demoulding cracking an…… MORE

Shell shortage, also known as lack of glue, insufficient filling, insufficient injection, incomplete plastic shell, etc., is the most common problem we encounter in plastic shell injection molding every day, which is usually manifested in the end of the molding area and the position of f…… MORE

With the development of the times, plastic shell has been more and more deeply into our life. Many friends can't avoid using plastic shell to deal with various things, such as the protection of computer power supply, the protection of safety tools, and the shell of power bank we use is p…… MORE

With the continuous implementation of various epidemic prevention and control measures, although the total number of confirmed cases in the country is still on the rise, the data in other regions except Wuhan have begun to decline. At the same time, enterprises are returning to work in s…… MORE

During the injection molding process, the dents of the plastic shell are shrinkage dents generated after the plastic is cooled and hardened, which mainly appear in the thick wall of the plastic shell, ribs, shell, nut insert back, etc. 1、 Equipment: (1) insufficient feeding, serious wear…… MORE

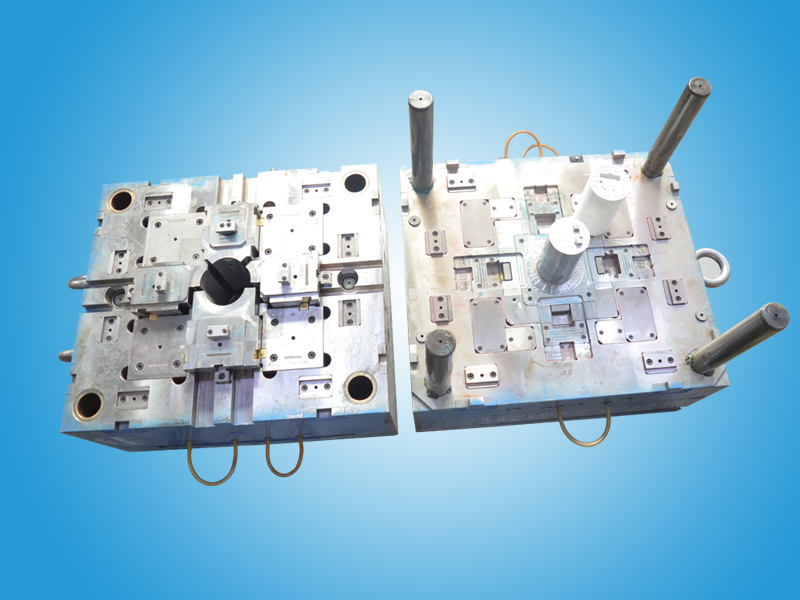

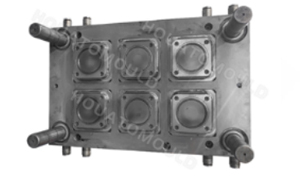

The finished product quality and processing cost of injection mold are closely related to the quality of injection mold. Therefore, it is particularly important to judge the quality of injection mold before processing. How to judge the quality of an injection mold? Injection molding: how…… MORE

The shell of medical devices is usually manufactured by low-pressure pouring, which is produced by simple molds, such as aluminum mold, resin mold, ABS mold, etc. Resin molds are commonly used, because the cost of resin molds is lower than aluminum molds, and the speed of making molds is…… MORE

Omnidirectional injection molding is to inject the plastic melt into the middle of the closed mold cavity under high pressure, and then heat it to solidify, so as to obtain the plastic product exactly the same as the mold cavity. The following is a detailed explanation of the basic views…… MORE

What is the manufacturing process of insert molding? Insert molding is the process of forming thermoplastic materials around preformed parts (inserts) to manufacture parts containing various materials. Inserts are usually metal parts used to enhance the mechanical properties of plastic p…… MORE

Overview plastic extrusion molding is to heat the plastic to the flowing state, then make it pass through the plastic mold under a certain pressure, and then make it into a continuous profile after shaping. There are many kinds of plastic products processed by extrusion, such as pipe, fi…… MORE