療器材類/檢測儀外殼.jpg)

在醫(yī)療設(shè)備中,醫(yī)療器械外殼往往是實現(xiàn)絕緣性能和外觀設(shè)計性能使用中的感官和便利性的重要載體,因此外殼的外觀直接影響醫(yī)療設(shè)備使用中的感官,在外殼的裝配過程中,有些部件需要使用螺釘固定,螺釘?shù)男孤┰谕饷鏁绊懲鈿さ恼w美觀性。一種新型醫(yī)療器械外殼,可以避免螺釘?shù)耐饴瑥亩粫绊懲鈿さ恼w美觀性。新型醫(yī)療器械外殼,包括殼體,……

MORE

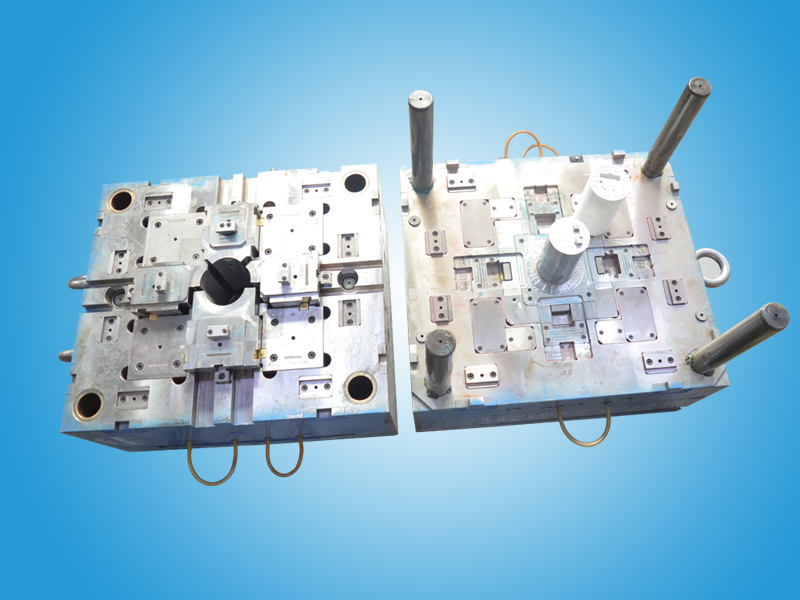

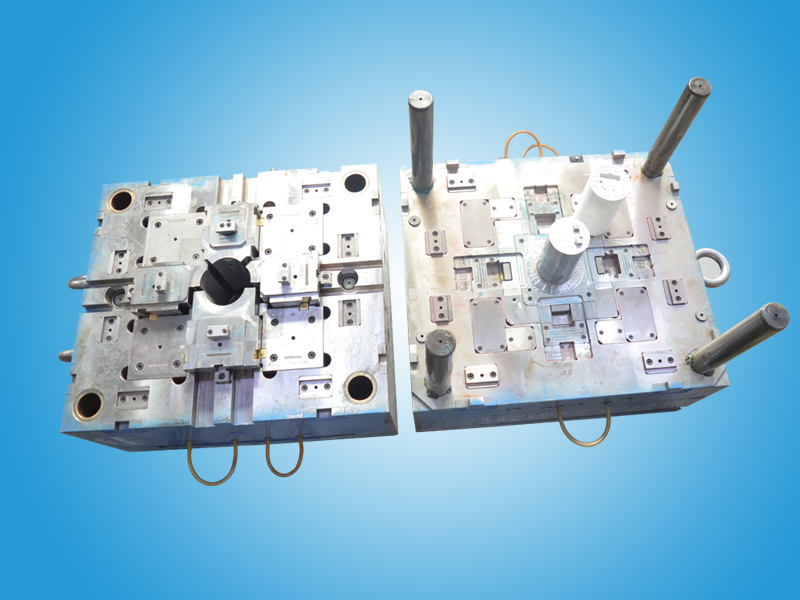

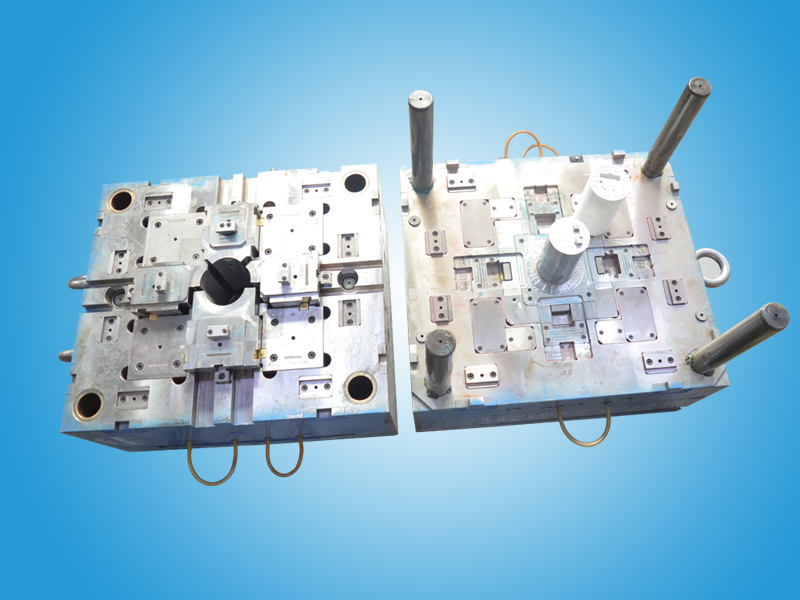

High precision dies should not only have high machining accuracy, but also have good machining quality. Generally speaking, the tolerance range should be controlled at the micron level. Only high-precision molds can ensure that the products reach a certain accuracy and product qualificat…… MORE

備/投影機2.jpg)

The surface treatment of plastic products mainly includes coating treatment and coating treatment. Plastics generally have high crystallinity, low polarity or non polarity, and low surface energy, which will affect the adhesion of the coating. Because plastic is a non-conductive insulato…… MORE

Now people have far more requirements for plastic shells than before, and now it is more and more common to choose custom plastic shells. In some links of developing custom plastic shells, the steps of customizing plastic shells are very concerned. If you want to know what the steps of c…… MORE

The external and internal shapes of plastic parts are directly formed by the cavity and core. The processing of these complex three-dimensional surfaces is difficult, especially for the processing of the cavity blind hole forming surface. If the traditional processing method is adopted, …… MORE

Now most people are familiar with plastic shells, because there are all kinds of plastic shells in people's life, but we only know that the application field of plastic shells is very common. But I don't know how the plastic shell is processed. So, in order to let more and more people un…… MORE

Injection molding is a common production method in industrial manufacturing. Is an important tool for mass production, so what are the basic requirements for injection mold processing? (1) Ensure the quality of injection mold processing. The quality of injection mold processing refers to…… MORE

備/投影機1.jpg)

There are many types of moulds. Only plastic moulds can be divided into: (1) injection moulds; (2) Blow mold; (3) Blister mold; (4) Extrusion die; (5) Foaming mold; (6) Silicone mold. Injection mold can be divided into two parts: hot runner mold and cold runner mold according to differen…… MORE

The key link of injection molding is to make various forms of plastic into products or blanks with required shapes. There are more than 30 injection molding methods. Its choice mainly depends on the type of plastic, the initial shape, and the shape and size of the product. Today, the inj…… MORE

塑膠外殼模具結(jié)構(gòu)設(shè)計有哪些步驟?隨著人們審美觀念的不斷提高,塑膠外殼模具已經(jīng)成為一種很受歡迎的塑膠外殼產(chǎn)品。我們先來看看塑膠外殼加工的一般步驟。 一、塑膠外殼的技術(shù)分析 在模具設(shè)計之前,設(shè)計師要充分分析研究自己的塑料產(chǎn)品是否符合注塑成型的原理,這就需要和產(chǎn)品設(shè)計師進行仔細的磋商,達成共識。其中包括對……

MORE

塑料注塑模具加工的精度決定了塑膠制件的精度,因此對塑料注塑模具加工精度的控制是很重要的。那么我們在模具加工的過程中應(yīng)該如何對精度進行控制呢? 1、優(yōu)化塑料注塑模具加工工藝 不同的模具結(jié)構(gòu)應(yīng)選擇不同的加工方法。在控制模具加工精度的時候,要滿足實際的工作要求,選擇合適的模具加工的工藝并嚴(yán)格執(zhí)行。各種塑料……

MORE