Injection molding is a method that the plastic material is heated and melted in the heating barrel of the injection molding machine, and then the melt is pushed into the mold cavity of the closed mold through the reciprocating screw for molding. It can not only produce high-precision and…… MORE

Injection molding is a field with high technical content. In addition to years of experience accumulation, we should also have a heart that is good at discovery and be familiar with the whole injection molding process. To correctly learn all aspects of injection molding processing requir…… MORE

Is there any special structure and special requirements for mold manufacturing? For example, the mold needs a manipulator to assemble and disassemble. If this problem is not considered in the mold acceptance process, it will certainly affect the installation and service life. This also s…… MORE

With the intensification of competition in the home appliance industry, it requires us to try our best to reduce costs and enhance the price advantage of products in order to win more orders. In order to enhance the competitiveness of products, maintain a good profit margin and low cost,…… MORE

Overflow, also known as flash and overflow, usually occurs at the opening and closing position of the mold. For example, the parting surface of the mold, the gap of the insert, the hole of the ejector rod and so on. If the overflow cannot be removed in time, part of the injection mold wi…… MORE

In the process of plastic injection molding, if the temperature is too high or too low, it will have an adverse impact on the molded injection molding products, which will seriously affect the waste of molded injection molding products. Therefore, the temperature control in the injection…… MORE

Many household appliances used in our home are made of plastic materials. These plastic shells gradually turn yellow with the increase of service life or the corrosion of substances in the environment. So what can we do to prevent and deal with the yellowing of the electrical shell? The …… MORE

The 5g era is coming, and the material of mobile phone shell is changing from plastic to metal and to non-metal. Plastic is favored by the middle and low-end market because of its low cost. From IML to IMT process, the plastic becomes rich and beautiful, which can approximate the 3D opti…… MORE

3C electronic shell materials need flame retardancy, balance of strength and toughness, thin-wall molding and dimensional stability, so halogen-free flame retardant pc/abs is the best choice. However, halogen-free flame retardant pc/abs is not omnipotent. When it is used as a 3C electron…… MORE

Engineering plastics are widely used in manufacturing industrial parts and various shells because of their excellent properties - high strength, heat resistance, impact resistance, aging resistance and so on. But the cracking of plastic products is also a headache, which is caused by mol…… MORE

This kind of composite material called tepex is a semi-finished plate (organic plate), which is also used for lightweight structural parts in the automotive industry. Its matrix is composed of polyamide 6 (PA6), polypropylene (PP), polycarbonate (PC), thermoplastic polyurethane (TPU) or …… MORE

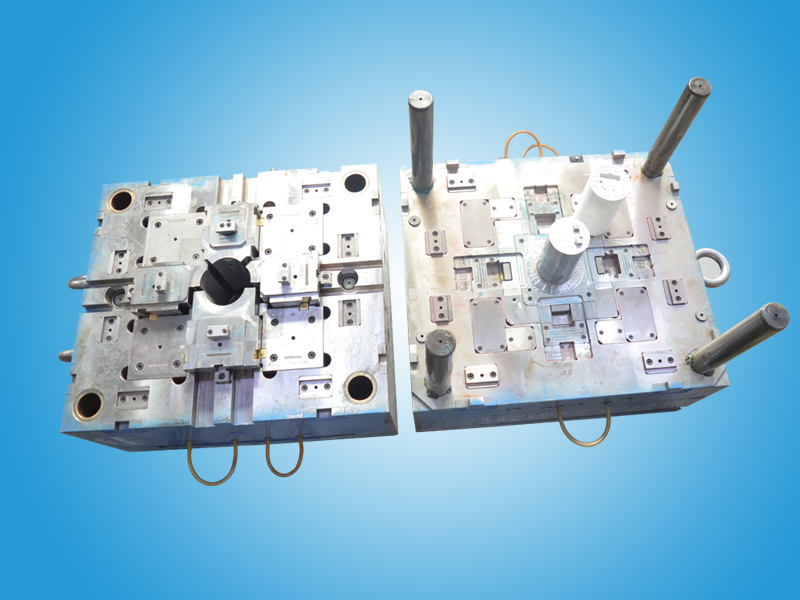

General classification of molds: it can be divided into plastic molds and non plastic molds: (1) non plastic molds include: casting molds, forging molds, stamping molds, die-casting molds, etc. A. Casting mold - faucet, pig iron platform B, forging mold - Auto body C, stamping mold - com…… MORE