Injection molding is an industry with wide knowledge, strong technology and strong practicality. Plastic raw materials, toner, nozzle materials, molds, injection molding machines, peripheral equipment, fixtures, sprays, various auxiliary materials and packaging materials are used in the …… MORE

Factors affecting the injection molding process: factors affecting the shrinkage of thermoplastic include: volume changes caused by plastic crystallization during the molding process, strong internal stress, large frozen residual stress in plastic parts, and strong molecular orientation.…… MORE

1. 45 high quality carbon structural steel, commonly used medium carbon quenched and tempered steel main features: commonly used medium carbon quenched and tempered steel, with good comprehensive mechanical properties, low hardenability, and easy to crack during water quenching. Small pa…… MORE

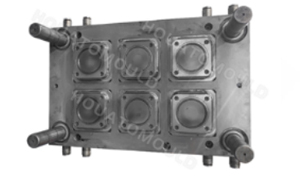

In order to improve the performance of the mold, many manufacturers will process the mold properly. Mold processing refers to the processing of forming and punching tools. In addition, it also includes cutting die and die-cutting die. However, in many cases, the mold is processed. It wil…… MORE

When the plastic parts of injection products are ejected from the mold, if the ejector pin is used, the ejector rod will often leave deep or shallow marks on the plastic parts. If these traces are too deep, the so-called top white phenomenon will appear. In serious cases, the so-called t…… MORE

1、 Advantages of plastic material: low cost, many shape changes, light weight, strong confidentiality, and can realize three prevention functions such as water and dust prevention. Plastic Bluetooth speakers are common shell materials in the market. According to incomplete statistics, mo…… MORE

Common automotive plastic parts include: instrument panel body frame, battery support, front-end module, control box, seat support frame, spare wheel seat, fender, chassis cover, sound insulation panel, rear door frame, etc. most automotive plastic parts panels adopt engineering plastics…… MORE

The camera shell is usually used to maintain the camera. Most scenes of the camera are applied indoors, which is a big test about the waterproof and hardness of the camera shell. With the rapid development of the security industry, there are many camera shell brands in the market. Under …… MORE

The common materials of medical device shells are FRP and ABS plastic. What is the difference between them? An important component of glass fiber reinforced plastics is glass fiber plus epoxy glue. In short, it is glass fiber epoxy board. The shell made of this kind of material by medica…… MORE

Maintenance methods: 1. Inspection: determine the deformation and damage of automotive plastic parts through inspection. 2. Fastening: fastening is an important maintenance operation to prevent parts from loosening. Automotive plastic parts should be tightened and replaced if necessary. …… MORE

There are two main manifestations of plastic aging: first, plastic products harden and crack. Second, plastic products become soft and sticky. So, how to deal with sticky plastic shell? Let's study together! 1. Blow it with a hair dryer and bake it to remove the glue. 2. Try an eraser. B…… MORE

The classification of small household appliances mainly includes: microwave ovens, rice cookers, electric irons, electric heaters, vacuum cleaners, electric fans, hair dryers, water dispensers, induction cookers, electric hotpots and electric heating kettles, air humidifiers, electric sh…… MORE